Cork

Prototypes

Prototypes

Photo-Fenton Prototype for Solar Decontamination

Photo-Fenton Prototype for Solar Decontamination

ICMC researchers developed a solar decontamination prototype within the Riteca II-Ergosuber project framework, using the Photo-Fenton process. This technology allows for an advanced use of solar energy based on solar ultraviolet radiation, which is collected by the mirrors of a piece of equipment designed for the purpose, in order to help eliminate the organic matter that is present in this type of water.

This method achieves effective purification of the water from the organic content in little time, thus avoiding the environmental damage caused by its discharge. The results obtained indicate that a reduction of over 50% of the contaminant content was attained without the need to subject wastewater to any previous treatment.

This line of work was intended to offer an innovative solution for the cork industry that would improve its production processes in terms of the cost reduction of the purification process and the significant reduction of contaminants that are harmful for the environment.

Solar power concentration prototype used to assist the cork boiling system _PILOT SCALE

Solar power concentration prototype used to assist the cork boiling system _PILOT SCALE

The purpose of this prototype is the generation of thermal energy to be used to heat up the water necessary in the cork boiling process. It is based on solar power concentration technology supplemented with biomass.

This pilot plant was installed in the Institute of Cork, Wood and Wood Charcoal. It included equipment and instruments that allow for the conversion of solar power into thermal power and also for the final transfer of thermal power to the boiler where the cork will be put for boiling once the reference temperature for this process is achieved.

The development and testing of this prototype were conducted under the RITECA II project under the Spain – Portugal 2007-2013 Transnational Cooperation Operation Programme, the purpose of which was the integration of renewable energies that were not used until now into the cork transformation industry, as an innovative application to improve the production process in terms of energy and environment, as well as the reduction of the costs of the cork boiling process.

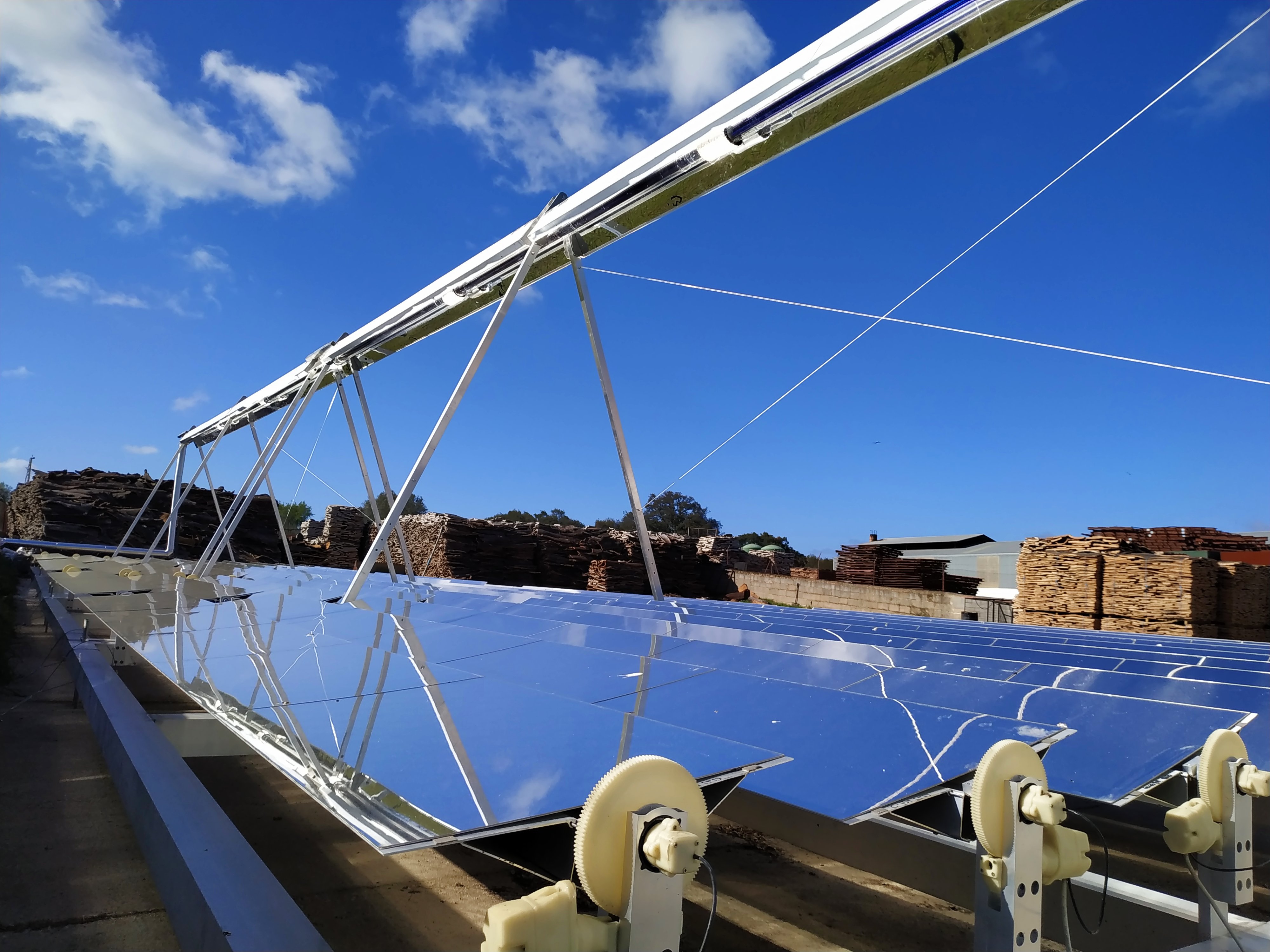

Mid-temperature solar power prototype used to assist the cork boiling system _INDUSTRIAL SCALE

Mid-temperature solar power prototype used to assist the cork boiling system _INDUSTRIAL SCALE

On the basis of the previous prototype that was tested on a pilot scale, we considered the continuation of this line of research and validated a new –this time heavy-duty- prototype- within the IDERCEXA project framework.

This piece of equipment includes new solar power collectors that are available in the market with a different solar power technology from the previously tested versions. Besides, the knowledge acquired from the previous experience allowed us to develop the current prototype with a higher degree of guaranteed success.

The end purpose is the assessment of a mid-temperature solar-metal power prototype with Fresnel linear technology, to be integrated in the processes of a cork boiling factory situated in San Vicente de Alcántara (Badajoz) in order to support the used water heating process. This will under no circumstances be used as a source of energy replacing the existing sources.

With the addition of the prototype, we will be able to assess the reduction of the production costs as a result of the reduction in fuel consumption; and the increase in the factory’s production capacity as the waiting times between cycles are also reduced in order to increase the temperature of water for boiling purposes.

The scope of this project goes from the design to the installation of the equipment, as well as the tests and trials and the technical and economic feasibility of the solution.