Charcoal

General information

General information

Charcoal is the solid product resulting from the burning of wood in supervised conditions and within a confined space such as a charcoal kiln. The air intake is monitored during the pyrolysis process (carbonisation) so that the wood does not burn completely, as would happen during full combustion. Instead, the wood is chemically decomposed in order to produce charcoal (solid stage), condensed wood tars (liquid stage) and gases (gaseous stage).

The wood carbonisation process has changed from being a handcrafted activity to a heavy-duty process in terms of production volumes, although not in terms of the monitoring of productivity or efficiency of the process, end product quality uniformity, process automation and control of emissions into the atmosphere.

Charcoal production considerably contributes to the economic and environmental sustainability of dehesa. In Extremadura alone there are approximately 125 companies developing this activity with a business volume reaching 90 million euros, according to the data provided by ASECAV, the association incorporating 18 companies not only situated in Extremadura, but also in Andalusia, Castilla-Leon and Madrid, which have come together with the purpose of improving and modernising the charcoal industry.

According to the publications of the official gazette of Extremadura, since 2013 to date our Autonomous Region has maintained 64 industrial facilities with Unified Environmental Authorisation to produce charcoal or charcoal briquettes, with a total of 181 kilns and a maximum production capacity of 85,000 tons/year of charcoal and 12,800 tons/year of briquettes.

Technological Innovation of the Production Processes

Technological Innovation of the Production Processes

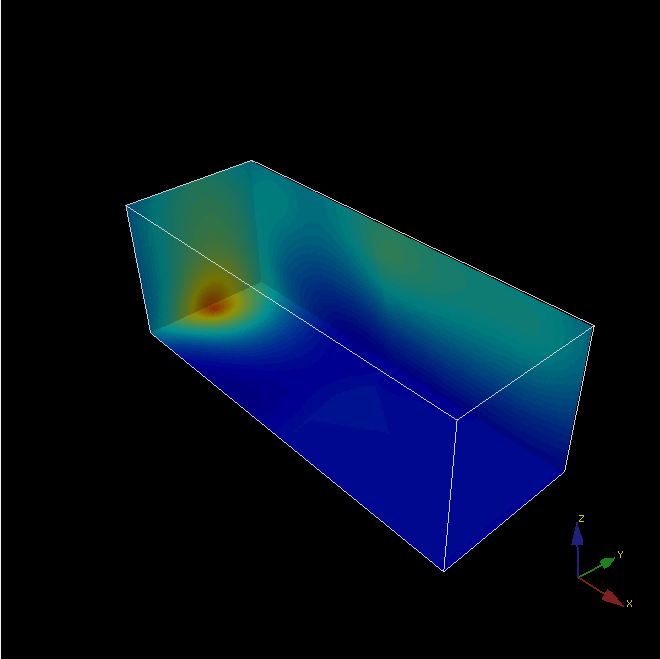

From the point of view of the industrial process and leaving other factors aside, the manufacture of charcoal has technical weaknesses in the short, medium and long-terms. All of them include the reduction of gas and particle emissions into the atmosphere, the increase in productivity and process efficiency, and the improvement of the end product quality uniformity.

CICYTEX has a line of research that focuses on technological innovation of productive processes to obtain charcoal and briquettes (optimisation of the production process, incorporation of renewable energies and environmental improvements) and thus assists with the following industry-proposed specific measures:

New production processes intended to obtain a more uniform product quality.

Introduction of corrective measures in current kilns in order to restrict the emission of contaminant gases and solid particles.

Improved efficiency and energy recovery, thermophysical pre-treatments for the wood to be charred.

Recovery of the enthalpy of the emissions generated.

Provision of sensors and automation to traditional kilns.

Insulation improvement of charcoal kilns.

Product improvement

Product improvement

On the other hand, improving the end product quality is also an objective we pursue, with this line including the development of new products and innovation applications for charcoal, such as binders for briquettes, biomedical residues for the production of charcoal or soot and charcoal as an alternative source of energy for cooking.

In spite of the fact that technological innovation and product improvement are two differentiated lines, they have a mutual impact on each other.